Rapid Tooling Services

- Production-grade tooling in a shorter time

- Cost-effectiveness

- Improved accuracy

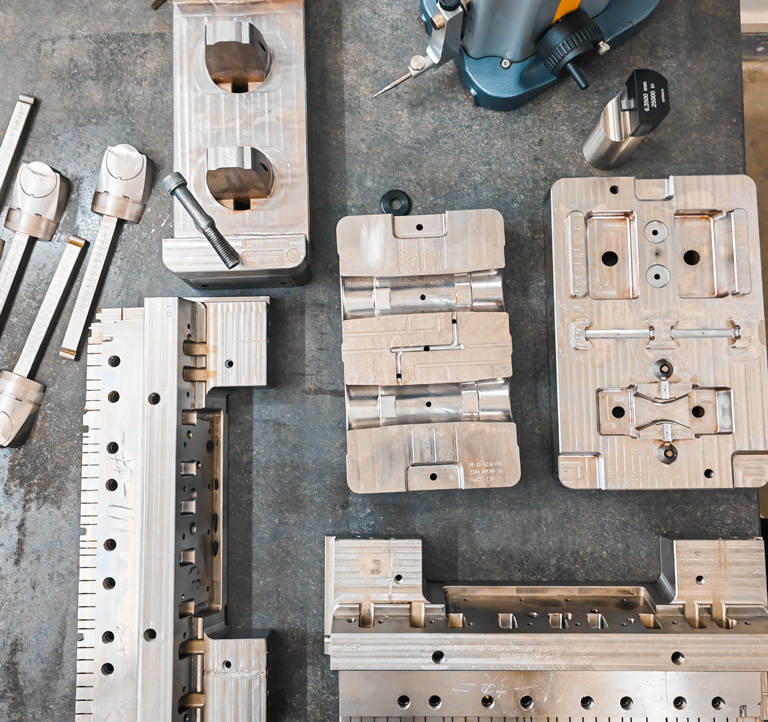

Rapid tooling is a manufacturing process that involves the use of specialized techniques and technologies to quickly produce production-grade tooling for the production of parts. Rapid tooling allows manufacturers to produce tooling in a shorter time frame than traditional methods, helping to accelerate the manufacturing process. There are several techniques that can be used for rapid tooling, including 3D printing, CNC machining, and injection molding. Rapid tooling can be used to produce tooling in a variety of materials, including metals, plastics, and composites. It is often used for the production of small quantities of parts or for prototyping, as it allows for the production of tooling without the need for expensive and time-consuming traditional methods.

why Choose Us

Our company offers a range of features that make us stand out in the market. Some of these features include:

High Quality

We pride ourselves on producing top-quality products that meet the needs and requirements of our customers.

Fast turnaround times

We understand the importance of meeting deadlines, so we work efficiently to ensure that our customers receive their products in a timely manner.

Wide range of materials

We offer a wide range of materials to choose from, including plastics, metals, and composites. This allows our customers to select the material that best meets their needs.

Customization options

We offer customization options to meet the specific needs and requirements of our customers.

How To Work With Us

Our company offers a rapid tooling process that involves the production of molds using steel or aluminum, hand-loaded inserts, and a stocked mold base. This technique is particularly useful for small-volume productions due to its speed and cost-effectiveness.

Our rapid tooling service is designed to deliver parts in the shortest possible timeframe, making it an ideal choice for customers who need their products delivered quickly. The typical working order for our rapid tooling service includes:

Submit Request

Upload your 3D file or any design work.

DFM & Quotation

We usually get back to you within 24 hours.

Casting & Machining

Once receiving the deposit, we start working on the project.

Shipping

Packaged, labeled, and shipped to your door right on time

Rapid Tooling Services, production-grade tooling?

Rapid Tooling Materials

There are several materials that can be used for rapid tooling, including:

Metals: Metals such as steel and aluminum are commonly used for rapid tooling, as they are strong and durable, and can withstand high temperatures and pressures.

Plastics: Plastics such as polycarbonate (PC), acrylonitrile butadiene styrene (ABS), and polystyrene (PS) are commonly used for rapid tooling, as they are lightweight and easy to work with.

Composites: Composites such as carbon fiber reinforced plastic (CFRP) and glass fiber reinforced plastic (GFRP) can also be used for rapid tooling, as they offer a combination of strength and lightweight properties.

The choice of material for rapid tooling will depend on the specific needs and requirements of the tooling, including the intended use, mechanical properties, and cost.

Industry Application

Rapid tooling is used in a variety of industries to produce small quantities of parts or prototypes. Some common applications of rapid tooling include:

Automotive: Rapid tooling is used in the automotive industry to produce prototypes and low-volume production parts for testing and evaluation.

Aerospace: Rapid tooling is used in the aerospace industry to produce prototypes and low-volume production parts for testing and evaluation.

Medical: Rapid tooling is used in the medical industry to produce prototypes and low-volume production parts for testing and evaluation.

Consumer goods: Rapid tooling is used in the consumer goods industry to produce prototypes and low-volume production parts for testing and evaluation.

Industrial: Rapid tooling is used in the industrial sector to produce prototypes and low-volume production parts for testing and evaluation.

Overall, rapid tooling is a valuable tool for a wide range of industries, allowing manufacturers to quickly and cost-effectively produce small quantities of parts or prototypes for testing and evaluation.

Free & Quick

Benefits of Rapid Tooling

Rapid tooling is a manufacturing process that involves the use of specialized techniques and technologies to quickly produce production-grade tooling for the production of parts. Some benefits of using rapid tooling include:

Speed: Rapid tooling allows manufacturers to produce tooling in a shorter time frame than traditional methods, helping to accelerate the manufacturing process.

Cost-effectiveness: Rapid tooling can be a cost-effective solution for producing small quantities of parts, as it eliminates the need for expensive and time-consuming traditional methods.

Improved accuracy: Rapid tooling techniques can produce tooling with a high level of accuracy, helping to ensure that the final parts meet the desired specifications.

Flexibility: Rapid tooling allows manufacturers to produce tooling in a wide range of materials and shapes, giving them flexibility in the production process.

Iteration: Rapid tooling enables manufacturers to quickly produce multiple versions of a tool, allowing them to iterate on their designs and make improvements.

Testing: Rapid tooling allows manufacturers to produce tooling for testing and evaluation, helping to ensure that the final parts meet the desired performance and functional requirements.