CNC Machining Service

- Quick Turn-around As Fast As 1 Day

- Tight tolerance down to 0.01mm

- Large in-house production capability

Certifications: IATF16949:2016 | ISO9001:2015

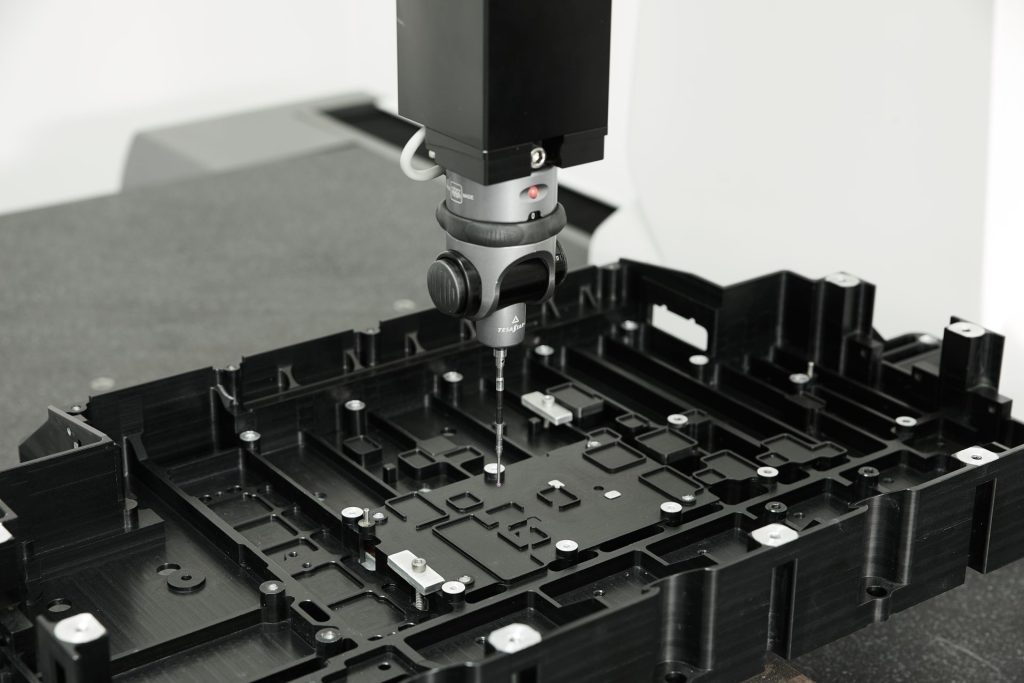

Superior Part offers precision CNC machining services using a range of high-precision equipment including 5-axis CNC machining centers, four-axis CNC machining centers, and EDM machines. Our machining shop has over ten years of experience in a variety of industries, including automotive, medical, and aerospace. Our team of over 200 people is dedicated to providing fast, precise, and versatile machining services, and we have successfully completed projects involving engine blocks, cylinder heads, rotary shafts, drive shafts, gears, gearboxes, brake drums, hubs, gear rocker arms, rocker shafts, jet engine parts, and medical device components.

why Choose Our CNC Machining Services

In-house Production Capability

We use the latest and best machinery in the industry to provide in-house capabilities that bring ideas to reality quickly. From manufacturing equipment to testing equipment, we have all the tools and machinery needed for success.

Experienced & Professional Team

Our experienced team of professionals is the backbone of our operations. We offer a wide range of materials to choose from, including sourcing materials from the market for our clients. In addition, we have over 30 different types of plastics and metals in-house for our customers to choose from.

Quick Turn-around

If you need your part ASAP, we can have it machined in as little as a few hours or even a few minutes, depending on the complexity of the design and the material used. Simply provide us with a 3D CAD file of your part, and our engineers will take care of the rest, including any difficult features that other manufacturers may not be able to handle.

Reliability & Certificated

IATF16949, ISO9001 certified. Our rapid prototype and product development process, combined with quick turnaround times, sets us apart from the competition. No matter how complex the part, we promise to deliver exactly what you need. Even if you have a difficult-to-machine part, our team can handle it. We have a track record of 100% on-time delivery.

Free & Quick

How To Work With Us

Submit Request

Upload your 3D file or any design work.

DFM & Quotation

We usually get back to you within 24 hours.

Casting & Machining

Once receiving the deposit, we start working on the project.

Shipping

Packaged, labeled, and shipped to your door right on time

Quality, Quick, Affordable!

CNC Machining Processes

CNC Milling Service

Our CNC milling service utilizes high-precision computer-controlled equipment to produce precise and intricate parts and components. With the ability to work with a variety of materials, including metals, plastics, and composites, our CNC milling service can produce parts with tight tolerances and complex geometries. Our team of experienced machinists and engineers ensure that each project is completed efficiently and to the highest quality standards. Contact us for all your CNC milling needs.

CNC Turning Service

Our CNC turning service uses computer-controlled lathes to produce precise and accurate parts with a high level of efficiency. We have the ability to work with a variety of materials, including metals, plastics, and composites, and can produce parts with tight tolerances and complex geometries. Our team of skilled machinists and engineers ensure that each project is completed to the highest quality standards. Contact us for all your CNC turning needs.

.jpg)

Materials Used In CNC Machining Services

We offer a wide range of materials for our customers to choose from, and can also source materials from the market to meet specific application needs. Some options include:

Plastic: Machining prototypes in plastic is a popular choice because it allows for review and testing of design and functionality from all angles.

Metal: CNC machining is particularly effective for machining metals, and we can produce prototypes as well as end-user parts for manufacturing in a variety of metals.

Other Materials: In addition to plastics and metals, we can also produce alloys and other custom materials upon request using CNC machining.

Popular Plastics Materials

ABS, ABS+PC, PC, PP, PEEK, POM, Acrylic (PMMA), Teflon, PS, HDPE, PPS, DHPE, PA6, PA66, PEI, PVC, PET, PPS, PTFE.

Popular Metal Materials

Aluminium, Brass, Copper, Magnesium, Titanium, Stainless Steel, Tin, Zinc

Tolerance Standards

Our CNC milling service provides highly accurate and precise milling with tolerances as tight as 0.001 – 0.005mm. Please note that tolerance can vary based on the material used and the geometry of the milled part. For more information, refer to the chart below:

| Tolerance Lever | Overall Dimension Range | ||||||

| Specifications | <<3, >0.5 | <<6, >3 | <<30, >6 | <<120, >30 | <<400, >120 | <<1000, >400 | <<2000, >1000 |

| Tolerance Standard | |||||||

| F | ±0.05 | ±0.05 | ±0.1 | ±0.15 | ±0.2 | ±0.3 | ±0.5 |

| M | ±0.1 | ±0.1 | ±0.2 | ±10.3 | ±0.5 | ±0.8 | ±1.2 |

| C | ±0.2 | ±0.3 | ±0.5 | ±0.8 | ±1.2 | ±2 | ±3 |

| V | – | ±0.5 | ±1 | ±1.5 | ±2.5 | ±4 | ±6 |

Surface Finishing

Our CNC machining finish service provides a wide range of finishing options for your parts and components. The type of finish we recommend will depend on the specific requirements of your project, including the material used, the intended end use of the part, and any aesthetic considerations. Some common finishing options include:

Anodizing: This process creates a hard, protective layer on the surface of the part by electrochemically treating it. Anodizing can improve corrosion resistance and enhance the appearance of the part.

Painting: We offer a range of painting options, including powder coating, liquid painting, and electrostatic spraying. Painting can provide a durable finish and can be used to achieve a specific color or texture.

Polishing: Polishing can create a smooth, shiny finish on the surface of the part. It can be used to improve the appearance of the part or to enhance its functionality (e.g. by reducing friction).

Sandblasting: This process uses abrasive particles to create a rough, textured finish on the surface of the part. Sandblasting can be used to improve the adhesion of coatings or to create a specific appearance.

Plating: Plating involves depositing a thin layer of a different metal onto the surface of the part. Plating can provide a range of benefits, including improved corrosion resistance, enhanced electrical conductivity, and improved appearance.

Free & Quick