low-volume manufacturing services

- Low MOQ

- As fast as 1 day

- From Designing to Manufacturing

Certifications: IATF16949:2016 | ISO9001:2015

As a highly experienced organization in the market, we offer a range of low-volume manufacturing services, including injection molding, CNC machining, aluminum extrusion, die casting, and sheet metal fabrication. Our diversely skilled team sets us apart from our competitors and allows us to offer a range of specialized services. With years of experience in the industry, we are able to offer high-quality products and services to our customers.

why Choose Us

Greater flexibility

We have the ability to quickly and easily adapt to changes in demand and can produce smaller quantities of customized products.

Improved efficiency

We can often achieve higher levels of efficiency, as we are able to focus on smaller quantities of customized products rather than large volumes of standard products.

Reduced lead times

Low-volume manufacturing companies typically have shorter lead times than mass production companies, as we do not have the same level of setup and production costs.

Enhanced product quality

Low-volume manufacturing companies can often produce higher quality products, as we are able to devote more attention to detail and customization.

Our Working Process

Submit Request

Upload your 3D file or any design work.

DFM & Quotation

We usually get back to you within 24 hours.

Casting & Machining

Once receiving the deposit, we start working on the project.

Shipping

Packaged, labeled, and shipped to your door right on time

Quality Low-Volume Manufacturing Services

main Machining processes we offer

CNC Machining

Maximize your production capabilities with our advanced and highly precise CNC machining service. Our service includes 3, 4, and 5 axis machining, turning, milling, surface grinding, and EDM grinding. Our team of skilled machinists and state-of-the-art equipment ensure the production of high-quality parts with exceptional accuracy and attention to detail. Trust in our expertise to handle all of your CNC machining needs.

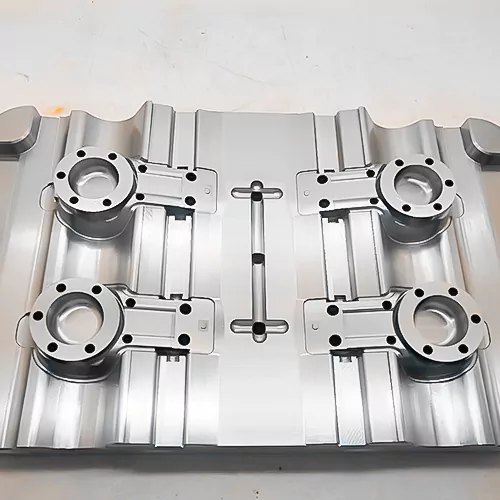

Plastic Injection Molding

Choose from a variety of colored or transparent plastics that can be molded into your desired shape quickly and at a competitive price. Our injection molding services offer a range of options to meet your specific needs, including a wide selection of materials, fast turnaround times, and market-competitive pricing. Trust in our expertise to provide high-quality, cost-effective injection molded parts that meet your specific requirements.

Material We Used

There are many materials that can be used for low volume manufacturing services, including:

Thermoplastics: These are a type of plastic that can be melted and reshaped multiple times. They include materials such as polyethylene, polypropylene, polystyrene, and ABS.

Thermosets: These are a type of plastic that cures to a hard, inflexible state when heated. They include materials such as polyurethane, epoxy, and silicone.

Elastomers: These are a type of rubber-like material that is highly flexible and elastic. They include materials such as silicone, neoprene, and natural rubber.

Metals: These are strong, durable materials that are commonly used in low volume manufacturing. Examples include aluminum, brass, copper, and steel.

Composites: These are materials made from a combination of two or more different materials, such as fiberglass reinforced plastic (FRP) or carbon fiber reinforced plastic (CFRP).

tolerance

At Superior Part, we understand the critical role precision plays in the manufacturing process, particularly for parts with strict tolerances. From prototypes to low-volume production runs, we offer a range of tolerances to meet the specific needs of our clients. Our minimum tolerance is 0.01mm, while our maximum tolerance is determined by customer requirements. We take into account factors such as thermal expansion, vibration, and wear and tear to ensure that our parts meet the required level of precision. Trust in our expertise to deliver precise, high-quality parts that meet your specific tolerance needs.

Finishing

There are several finishing services that can be used for low volume manufacturing, including:

Painting: Parts can be painted to add color or protect the surface from wear and damage.

Plating: Parts can be plated with metals such as gold, silver, or copper to improve their appearance or protect them from corrosion.

Anodizing: Anodizing is a process that involves electrochemically treating the surface of a metal part to improve its resistance to wear and corrosion.

Powder coating: Powder coating is a process that involves applying a dry, powdery paint to a surface and then curing it under heat to create a durable, protective finish.

Sandblasting: Sandblasting is a process that involves blasting abrasive particles at a surface to create a rough, textured finish.

Polishing: Polishing is a process that involves buffing a surface to a high shine using abrasive compounds or machines.

Heat treating: Heat treating is a process that involves heating and cooling metal parts to improve their strength, hardness, and other properties.

Benefits Low-Volume Manufacturing

There are several benefits to using low-volume manufacturing, including:

Flexibility: Low-volume manufacturing allows for the production of smaller quantities of customized products, making it a flexible option for companies with specific production needs.

Cost-effectiveness: Low-volume manufacturing can be more cost-effective than mass production for small production runs, as it eliminates the need for large-scale setup and production costs.

Speed: Low-volume manufacturing can be faster than traditional mass production methods, as it allows for the production of smaller quantities of customized products.

Quality: Low-volume manufacturing can often produce high-quality products, as it allows for a higher level of attention to detail and customization.

Innovation: Low-volume manufacturing can allow for more innovation and experimentation in product development, as it allows for the production of smaller quantities of customized products.

Responsiveness: Low-volume manufacturing can be more responsive to changes in demand, as it allows for the production of smaller quantities of customized products.

what is Low Volume Manufacturing

Low volume manufacturing refers to the production of small quantities of parts or products. It is typically used to produce prototypes, test market products, or meet small-scale production needs. Low volume manufacturing can be more flexible and cost-effective than mass production, as it allows for the production of smaller quantities of customized products. It is often used for the development and testing of new products, as well as for the production of specialized or niche products. Low volume manufacturing can be a useful option for companies that have limited production needs or that require the ability to quickly and easily adapt to changes in demand.

F.A.Q.

There are many materials that can be used in low-volume manufacturing, including thermoplastics, thermosets, elastomers, metals, composites, and ceramics. The specific material used will depend on the requirements of the product being produced.

Low-volume manufacturing is used in a variety of industries, including automotive, medical, consumer products, and electronics. It is a suitable option for companies in these industries that have limited production needs or that require the ability to quickly and easily adapt to changes in demand.

Some of the benefits of using low-volume manufacturing include flexibility, cost-effectiveness, speed, quality, innovation, and responsiveness. Low-volume manufacturing allows for the production of smaller quantities of customized products, making it a flexible option for companies with specific production needs. It can also be more cost-effective than mass production for small production runs, and it can be faster than traditional mass production methods. Low-volume manufacturing can also produce high-quality products with a higher level of attention to detail and customization,

Low-volume manufacturing is typically used for smaller production runs and allows for the production of customized products. In contrast, mass production is used for large quantities of standard products and is often less flexible and more expensive. Low-volume manufacturing can be a more cost-effective and flexible option for companies with specific production needs, while mass production is better suited for large-scale production of standard products.

Yes, low-volume manufacturing can often produce high-quality products, as it allows for a higher level of attention to detail and customization. Low-volume manufacturing can be used to produce prototypes or test market products, as well as specialized or niche products that require a high level of quality.