Injection Molding Services

- T1 sample as fast as 7 days

- 100+ Materials & finishing for choosen

- Affordable price

- One-stop solution

Certifications: IATF16949:2016 | ISO9001:2015

Injection molding is a manufacturing process used to produce parts and components by injecting molten material into a mold. The process begins by heating plastic resin pellets until they are melted, and then injecting the molten material into a custom-made mold under high pressure. The mold is designed to create a specific shape and size for the desired part or component. Once the plastic has cooled and solidified within the mold, it is removed and the process can be repeated to produce multiple copies of the same part. Injection molding is a quick and efficient way to produce large quantities of identical parts, and is commonly used in the production of automotive parts, electronic components, and household products.

why Choose Us

Certified Quality

It is important to choose a supplier that has a track record of producing high quality injection molded parts. We are IATF16949, ISO9001 certified.

Quick Delivery

Consider the supplier's lead times and delivery schedules to ensure that they can meet your production needs. We can make T1 sample as fast as 7 days.

In-house Capability

50+ injection molding presses up to 1000T. 100+ materials for choosen. We have the necessary equipment and expertise to handle your specific injection molding needs with equipments, the materials and finishes required.

Affordable Price

While cost is often a major factor in the decision-making process, it is important to also consider the value that the supplier brings to the table. Look for a supplier that can offer competitive pricing, but also has the experience and capabilities to provide high quality parts that meet your requirements.

How To Work with us

Upload 3D File

Please submit a free quote request along with a detailed description and technical 3D drawing of your product.

DFM & Quotation

We typically respond within 24 hours.

mold-making & Machining

Once the deposit has been received, we will begin the initial work of mold design and preparation, as well as start manufacturing on the machines.

Shipping & Delivery

The finished product will be packaged, labeled, and shipped to your door at the designated time.

Bring your product ideas to life!

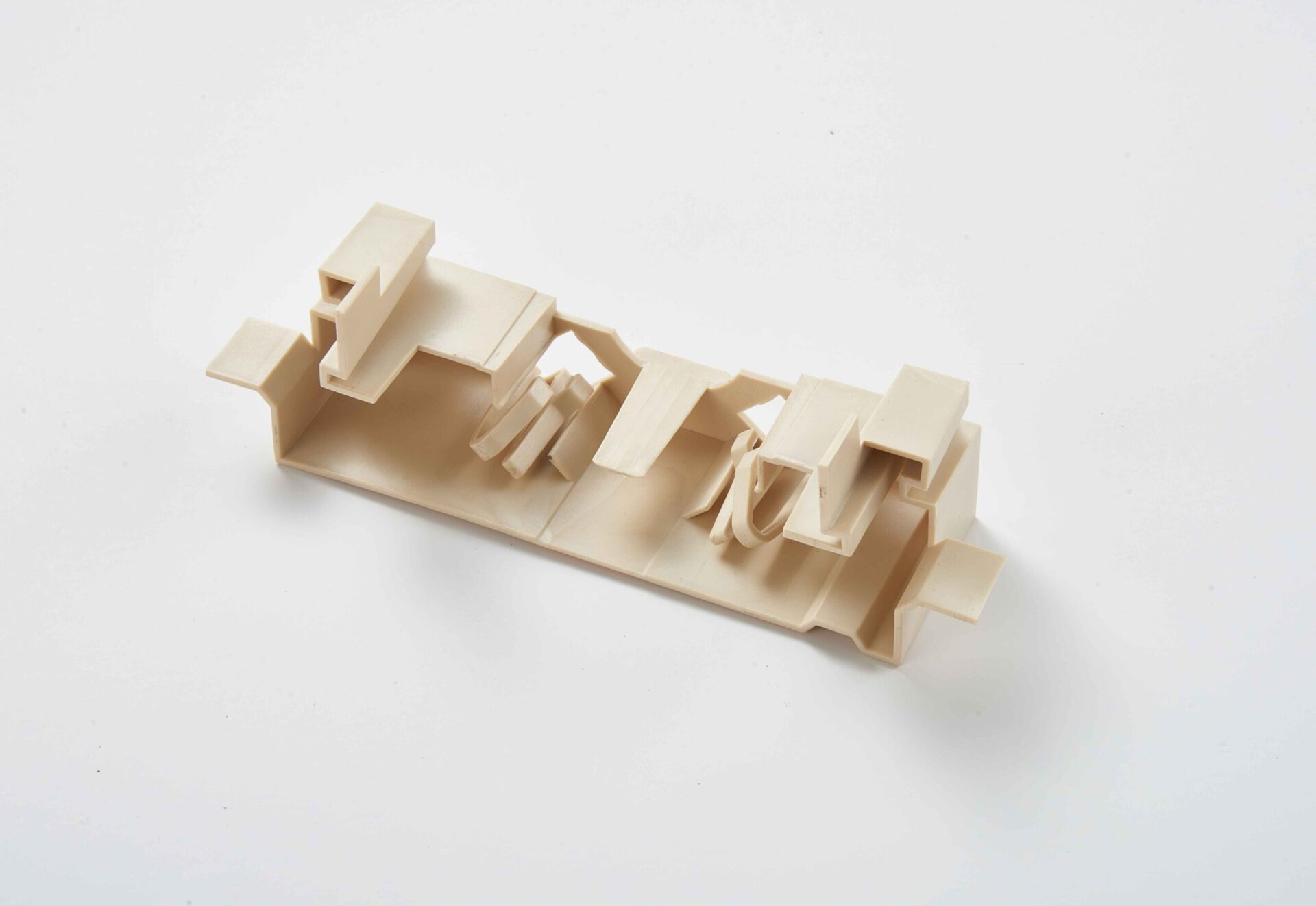

Our Advanced Injection Molding Options

Our company specializes in injection molding and can produce thousands of parts quickly to accelerate your product development process. We have a wide selection of materials to choose from, including over 100 plastic resin options in our inventory. We offer a variety of finishing options for molded end products and have expertise in plastic molding, insert molding, over molding, and family molding. Let us know how we can support your manufacturing needs.

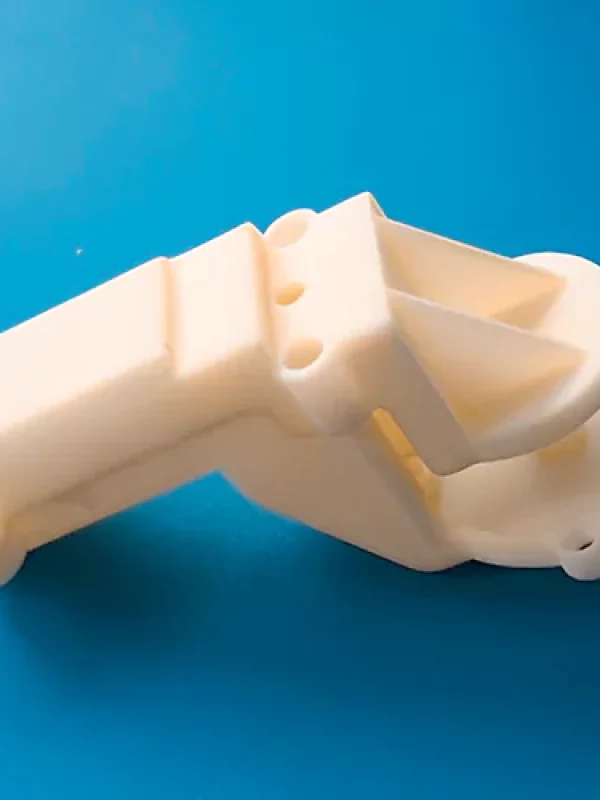

Plastic Injection Molding

Plastic injection molding is a process for producing parts by injecting molten plastic into a custom-designed mold. It is efficient and cost-effective for producing large quantities of identical parts and is used in many industries.

Insert molding is a process that combines a pre-manufactured component with plastic material to create a single part. It is used to add features or functionality to a part, or to reinforce or strengthen it. It allows for the integration of multiple materials and components into a single part and is a cost-effective way to add value to plastic parts.

Over molding is a process that adds a second layer of plastic material to a base material, creating a single part with multiple layers. It is used to improve the performance and versatility of the finished product.

A family mold is a type of injection mold that produces multiple copies of the same part in a single cycle. It contains multiple cavities and is used to mass-produce plastic parts cost-effectively.

Injection molding materials

We offer a wide range of plastic and polymer processing capabilities, including PPS, PP, POM, ABS, C-GF, HDPE, LDPE, PBT, TPV, PC, POE, PMMA, PA66, PA-GF, PS-PPE, TPE, and TPU. We also have the ability to use customer-provided materials. Our in-house collection of different injection molding materials allows us to effectively meet the needs of various industries.

Injection Molding finishing

We offer a number of surface finishes options to choose from. Customer’s aesthetics and functionality requirements dictate a particular finish method to use. We can finish your injection molded parts using any of the methods given below.

We offer a variety of surface finishes for our injection molded parts to meet the aesthetic and functional needs of our customers. Some of the finishes we offer include:

- Matte finish

- Gloss finish

- Textured finish

- Chromed finish

- Anodized finish

- Painted finish

Our team will work with you to determine the best finish option for your specific project.

Injection molding applications

Injection molding is widely used in a variety of industries due to its versatility and efficiency in manufacturing. It is employed in almost every sector, from automotive to medical to consumer products. Its manufacturing-friendly properties make it a popular choice for producing a wide range of plastic parts.

Automotive

Medical

Aerospace

Consumer Electronics

Military & Defense

Marine

Robotics & Automation

Oil and Gas Industry

Transportation

General Goods

Free & Quick

What is Injection Molding

Injection molding is a manufacturing process for producing parts by injecting molten plastic material into a mold. The mold is typically made of metal and is custom-designed for the specific part being produced. The process involves heating plastic resin to a liquid state and injecting it into the mold under high pressure. The mold is then cooled, and the solidified part is ejected from the mold. Injection molding is a fast, efficient, and cost-effective way to produce large quantities of identical plastic parts. It is widely used in a variety of industries, including automotive, medical, and consumer products.

Benefits of Using our Injection Molding Services

There are several benefits to using injection molding services, including:

Efficiency: Injection molding is a fast and efficient process, allowing for the production of large quantities of parts in a short amount of time.

Cost-effectiveness: Injection molding is a cost-effective way to produce large quantities of identical parts.

Precision: Injection molding allows for the production of parts with very tight tolerances and precise dimensions.

Versatility: Injection molding can be used to produce a wide range of parts in a variety of shapes and sizes, making it suitable for a variety of applications.

Consistency: The injection molding process produces parts that are consistent in quality and appearance.

Durability: Injection molded parts are strong and durable, making them suitable for use in a variety of applications.

Customization: Injection molds can be customized to produce parts with specific features or functionality, allowing for a high level of customization.

F.A.Q.

A wide range of materials can be used in injection molding, including thermoplastics, thermosets, elastomers, and other polymers. Common materials used in injection molding include polyethylene, polypropylene, polystyrene, and ABS.

Injection molding is widely used in a variety of industries, including automotive, medical, consumer products, and electronics. It is a versatile manufacturing process that is suitable for producing a wide range of parts in various shapes and sizes.

The lead time for an injection molding project will depend on the complexity of the part being produced, the size of the production run, and the availability of materials and equipment. Typically, lead times for injection molding projects range from a few weeks to a few months.

Injection molded parts can typically be recycled, depending on the material used. Many common injection molding materials, such as polyethylene and polypropylene, can be recycled. However, some materials, such as certain types of thermosets and certain additives, may not be recyclable. It is important to consult with the injection molding company about the recyclability of the materials being used.