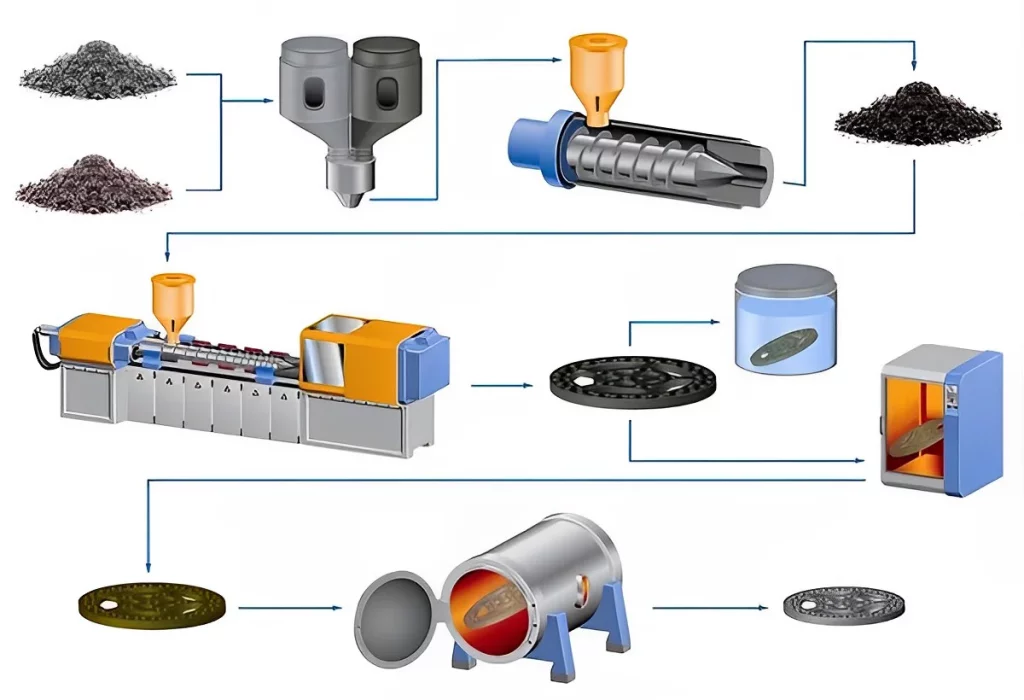

The injection molding process has become a go-to method in various manufacturing sectors, including the bicycle industry. By combining suitable metal powders with organic binders, manufacturers create a homogeneous feedstock that can be molded into various shapes using specialized tools. With subsequent chemical or solvent extraction and sintering, the resulting product gains the desired strength and form. In this section, we explore the versatility and potential benefits of injection molded chainrings in bicycles.

Unconventional Choices: Examining Injection-Molded Chainrings for Bicycles

The integration of injection-molded chainrings in bicycles raises intriguing questions. These components play a vital role in ensuring smooth gear transitions during rides. Cyclists might express concerns about the durability and performance of such chainrings. However, it is crucial to recognize that injection molding technology has advanced significantly, earning its credibility in various industries by delivering products with high precision and reliability.

Pioneering Progress: How Major Bicycle Manufacturers Embrace Innovation

To maintain a competitive edge and meet market demands, major players in the bicycle manufacturing industry are continually pushing the boundaries of materials and processes. The decision to incorporate injection-molded chainrings might be fueled by the pursuit of lighter, yet robust materials that can endure the rigors of cycling while adhering to cost constraints.

The Rise and Fall of the All-Plastic Bicycle: Lessons Learned

Looking back in history, the bicycle industry witnessed an ambitious endeavor to revolutionize transportation – the all-plastic bicycle. Originating as a response to the 1974 oil crisis, this bicycle, composed entirely of fiber-reinforced composite plastic (FRP), garnered significant attention. However, logistical challenges and technical limitations led to its eventual downfall. By examining this past failure, the industry can better understand the importance of balancing innovation with practicality.

Advancements in Material Innovation: Carbon Fiber and Beyond

Despite past setbacks, the bicycle industry has continued to be at the forefront of material innovation. Carbon fiber, often humorously referred to as the “new plastic,” has emerged as a game-changer, finding extensive use in high-performance bike frames and components. As technology progresses, more refined injection-molded materials may emerge as viable options for bicycles, showcasing improvements in strength, weight reduction, and affordability.

Navigating Challenges: Responsible Innovation for Cyclists’ Safety

While embracing novel approaches in bicycle manufacturing is exciting, it comes with its set of challenges and uncertainties. The paramount importance of rigorous testing and quality control cannot be overstated. Ensuring that these innovative solutions meet the high safety standards expected in the cycling world is of utmost importance. By maintaining this balance between progress and safety, the industry can confidently present reliable and safe products to cyclists worldwide.

Embracing a Dynamic Future in Bicycle Manufacturing

In conclusion, the integration of injection-molded chainrings into bicycles highlights the bicycle industry’s adaptability and resilience in the face of economic challenges. Learning from both successes and failures, such as the all-plastic bicycle, the industry can approach innovation with a balanced perspective. As technology advances and knowledge evolves, the future of bicycle manufacturing holds exciting possibilities, where innovative materials and processes may redefine the cycling experience for generations to come. By embracing responsible innovation, the industry can continue delivering cutting-edge bicycles that captivate cyclists and contribute to a sustainable and thrilling future of two-wheeled transportation.