With the advancement of industrial automation, understanding the mechanical components of CNC machines may not seem as crucial as before. According to a survey conducted among 200 CNC machine users, most respondents stated that the most challenging part of learning CNC is determining the necessary tooling, appropriate feed rates, as well as the width and depth of cutting required. While some parameters can be set through G-codes, achieving the desired output may require repeated trial and error.

Respondents also listed the difficulty of learning which tools to use and how to return or calibrate the machine before operation. For many users, a primary concern is workpiece fixation, ensuring that they remain securely in place during cutting to avoid any undesired movement. This involves selecting the right clamps, determining their quantity, and proper placement.

Interestingly, more respondents found the factors mentioned above more challenging than creating G-codes using CAM software. Although using CAM software may present its own complexities, most individuals do not view these issues as being as mechanically demanding.

Becoming an Expert in CNC Machining – How Long Does It Take?

One of the main advantages of CNC machining is its user-friendliness and ease of learning, especially for technicians with basic mechanical, mathematical, and logical skills. Such individuals can quickly adapt to CNC machines, even changing smaller G-codes within just ten days. However, becoming an expert in CNC machining requires a wealth of specialized knowledge, which may take several years or even longer to attain.

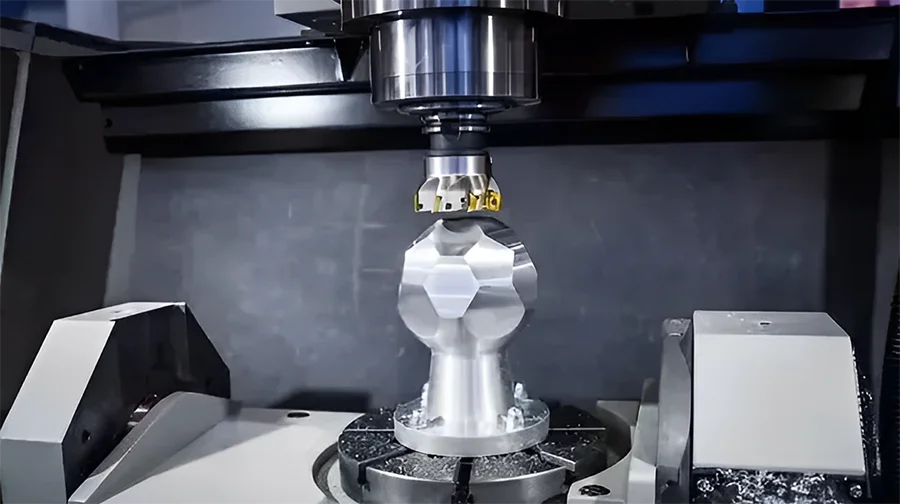

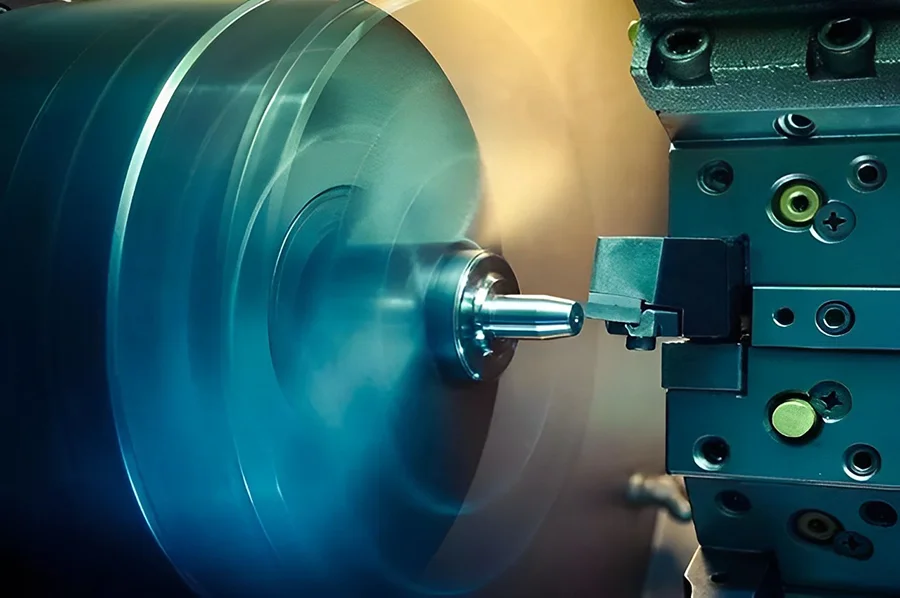

When evaluating and mastering the difficulty, the complexity of CNC machines should also be considered. The next step in complexity involves enabling tools to move in three dimensions. A basic CNC milling machine is a typical example of 3D CNC machining. The most complex type of CNC machine is the five-axis machine, combining three-dimensional motion with two additional rotations. Operating a five-axis machine involves intricate G-code programming that can contain over a million lines of code. Programming such a machine without CNC is a daunting task.

Does CNC Machining Require Workshop or Programming Experience?

CNC programming may not have the glitz and glamour of web developers or mobile app programmers, but it is undoubtedly a highly regarded and well-paying profession.

Traditional programmers may find learning G-codes relatively uncomplicated. What requires genuine learning is the standard G-code commands, their relevant parameters, and how they translate into real movements of tools and machines. G-code programming typically does not involve loops, complex logical functions, or even variable declarations.

However, programmers with limited experience may have limitations in understanding the capabilities of CNC machines. As emphasized earlier, the mechanical aspects of CNC machining are often the more challenging parts. Knowledge regarding tool usage and workpiece setup takes time and experience. CNC machine operators inevitably encounter mistakes, which lead to learning and understanding.

This highlights the value of traditional machining experience when delving into CNC machining. Even with basic G-code programming skills, experienced machinists can explore various ways to utilize CNC machines to their maximum potential. Nevertheless, this does not diminish the complexity of G-code programming, which still requires years to master.

Conclusion

With this analysis, you probably have an answer in your mind by now.

Learning CNC programming may be less difficult compared to standard coding (e.g., Java or PHP development). However, to become proficient and an “expert,” it takes not only a solid foundation of knowledge but also constant trial and error.

CNC machining is a technology that will continue to exist and become more prevalent in modern manufacturing practices. Considering this fact, if you are seeking a skill that can lead to well-paying jobs, learning CNC machining is undoubtedly worth considering.

As demonstrated, becoming an expert in CNC machining involves two aspects: machine operations and G-code programming. Among these two, undoubtedly, the experience in machine operations holds greater importance. Nonetheless, becoming a CNC expert requires years of learning and practice, often accompanied by making mistakes, which ultimately become invaluable experiences throughout your growth!

Learning CNC machining, from apprentice to proficiency, and working on projects alongside seasoned experts, presents numerous opportunities for hands-on experience. In many cases, three years may not be enough to become an expert in this field. To achieve true expertise, you need extensive experience and continuous accumulation of knowledge.