Rapid prototyping is a process that involves the use of computer-aided design (CAD) software and specialized manufacturing techniques to quickly produce a physical prototype of a product. Rapid prototyping allows designers and engineers to test and iterate on their designs in a short period of time, helping to accelerate the product development process.

There are several techniques that can be used for rapid prototyping, including 3D printing, CNC machining, and injection molding. These techniques can be used to produce prototypes in a wide range of materials, including plastics, metals, and composites.

Rapid prototyping is an important tool for product development, as it allows designers and engineers to quickly and easily produce physical prototypes for testing and evaluation. It can also be used to create functional prototypes or low-volume production parts.

why Choose Us

Speed

Our rapid prototyping service allows for the production of prototypes in a short period of time, helping to accelerate the product development process.

Quality

Our team of experienced professionals uses advanced technologies and techniques to produce high-quality prototypes that accurately represent the final product.

Cost-effectiveness

Our rapid prototyping service offers a cost-effective solution for producing prototypes and low-volume production parts.

Flexibility

We offer a range of rapid prototyping techniques and materials, allowing us to produce prototypes that meet the specific needs and requirements of our clients.

Our Working Process

Submit Request

Upload your 3D file or any design work.

DFM & Quotation

We usually get back to you within 24 hours.

Casting & Machining

Once receiving the deposit, we start working on the project.

Shipping

Packaged, labeled, and shipped to your door right on time

Leading rapid prototyping service

Rapid prototyping solutions

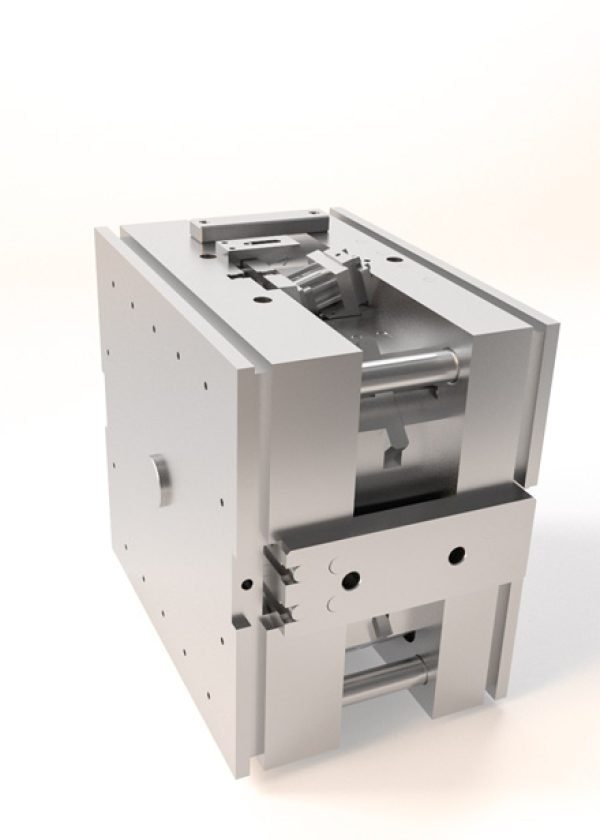

CNC Machining

Maximize your production capabilities with our advanced and highly precise CNC machining service. Our service includes 3, 4, and 5 axis machining, turning, milling, surface grinding, and EDM grinding. Our team of skilled machinists and state-of-the-art equipment ensure the production of high-quality parts with exceptional accuracy and attention to detail. Trust in our expertise to handle all of your CNC machining needs.

Plastic Injection Molding

Choose from a variety of colored or transparent plastics that can be molded into your desired shape quickly and at a competitive price. Our injection molding services offer a range of options to meet your specific needs, including a wide selection of materials, fast turnaround times, and market-competitive pricing. Trust in our expertise to provide high-quality, cost-effective injection molded parts that meet your specific requirements.

Rapid Prototyping in a Variety of Materials

There are a wide range of materials that can be used for rapid prototyping, including:

Plastics: Plastics are a common material for rapid prototyping, as they are inexpensive, easy to work with, and available in a wide range of colors and properties. Commonly used plastics for rapid prototyping include ABS, polycarbonate, and nylon.

Metals: Metals such as aluminum, brass, and stainless steel can be used for rapid prototyping through techniques such as CNC machining and metal casting.

Composites: Composites are materials made from a combination of two or more materials, such as fiberglass reinforced plastic (FRP). Composites can be used for rapid prototyping through techniques such as 3D printing and layering.

Other materials: include silicone, rubber, and wood.

The choice of material for rapid prototyping will depend on the specific needs and requirements of the prototype, including its intended use, aesthetics, and mechanical properties.

Tolerance for rapid prototyping

Tolerance refers to the allowable deviation from the desired dimensions of a part. In rapid prototyping, tolerance is an important factor to consider as it can affect the fit and function of the prototype.

Tolerance standards for rapid prototyping can vary depending on the specific needs and requirements of the prototype and the production process being used. In general, tolerance standards for rapid prototyping are typically looser than those for mass production, as prototypes are often used for testing and evaluation rather than for final production.

It is important to carefully consider tolerance when designing a prototype and to communicate tolerance requirements clearly with the rapid prototyping service provider to ensure that the finished prototype meets the necessary specifications. Factors that can affect tolerance in rapid prototyping include the complexity of the part, the material being used, and the production process being employed.

Surface Finishing

There are several factors to consider when choosing a rapid prototyping finishing service, including:

The intended use of the prototype: Different finishing services may be more suitable for different applications, so it is important to consider how the prototype will be used.

Aesthetics: The appearance of the prototype is often an important factor, so it is important to consider how different finishing services will affect its appearance.

Cost: Different finishing services can have different costs, so it is important to consider budget constraints when choosing a service.

Durability: The durability of the prototype is often an important factor, so it is important to consider how different finishing services will affect its lifespan.

Time: Some finishing services may take longer than others, so it is important to consider the timeline for the prototype when choosing a service.

Compatibility with the prototype material: Some finishing services may not be suitable for certain materials, so it is important to consider the material of the prototype when choosing a service.

Ultimately, the best finishing service for a rapid prototype will depend on the specific needs and requirements of the prototype and the intended use. It is important to carefully consider these factors and communicate them clearly with the finishing service provider to ensure that the finished prototype meets the necessary specifications.

Free & Quick

What is rapid prototyping?

Rapid prototyping is a manufacturing process that enables the rapid production of physical prototypes using specialized technologies and techniques. This process allows designers and engineers to quickly produce prototypes of their products, which can be used for testing, evaluation, and demonstration purposes. Rapid prototyping can be used to produce prototypes in a variety of materials, including plastics, metals, and composites, and is an important tool for product development, helping to accelerate the design and prototyping process.

There are several techniques that can be used for rapid prototyping, including 3D printing, CNC machining, and injection molding. These techniques allow for the rapid production of prototypes in a variety of shapes, sizes, and materials, depending on the specific needs and requirements of the prototype.

Rapid prototyping is often used in the early stages of product development to create prototypes for testing and evaluation, as it allows designers and engineers to quickly and easily produce physical versions of their designs. It is also used to create functional prototypes or low-volume production parts for a variety of industries, including automotive, aerospace, medical, and consumer goods.

Overall, rapid prototyping is a valuable tool for product development, allowing designers and engineers to quickly and easily produce prototypes that can be used for testing, evaluation, and demonstration purposes.

Advantages of using Rapid Prototyping

There are several advantages to using rapid prototyping in product development, including:

Speed: Rapid prototyping allows designers and engineers to produce prototypes in a short period of time, helping to accelerate the product development process.

Cost-effectiveness: Rapid prototyping can be a cost-effective solution for producing prototypes and low-volume production parts, as it allows for the production of small quantities of parts without the need for expensive tooling.

Flexibility: Rapid prototyping allows for the production of prototypes in a wide range of materials and shapes, giving designers and engineers flexibility in the design and testing process.

Improved accuracy: Rapid prototyping allows for the production of prototypes with a high level of accuracy, helping to ensure that the final product meets the desired specifications.

Iteration: Rapid prototyping allows for the quick and easy production of multiple versions of a prototype, allowing designers and engineers to iterate on their designs and make improvements.

Testing: Rapid prototyping allows designers and engineers to produce prototypes for testing and evaluation, helping to ensure that the final product meets the desired performance and functional requirements.

F.A.Q.

Yes, rapid prototyping can be used to produce low-volume production parts as well as prototypes. The specific technique and materials used may vary depending on the specific needs and requirements of the production parts.

The accuracy of prototypes produced through rapid prototyping can vary depending on the technique being used and the specific requirements of the prototype. In general, rapid prototyping allows for the production of prototypes with a high level of accuracy.

Some common techniques used for rapid prototyping include 3D printing, CNC machining, and injection molding.

There are a wide range of materials that can be used for rapid prototyping, including plastics, metals, and composites. The choice of material will depend on the specific needs and requirements of the prototype, including its intended use, aesthetics, and mechanical properties.